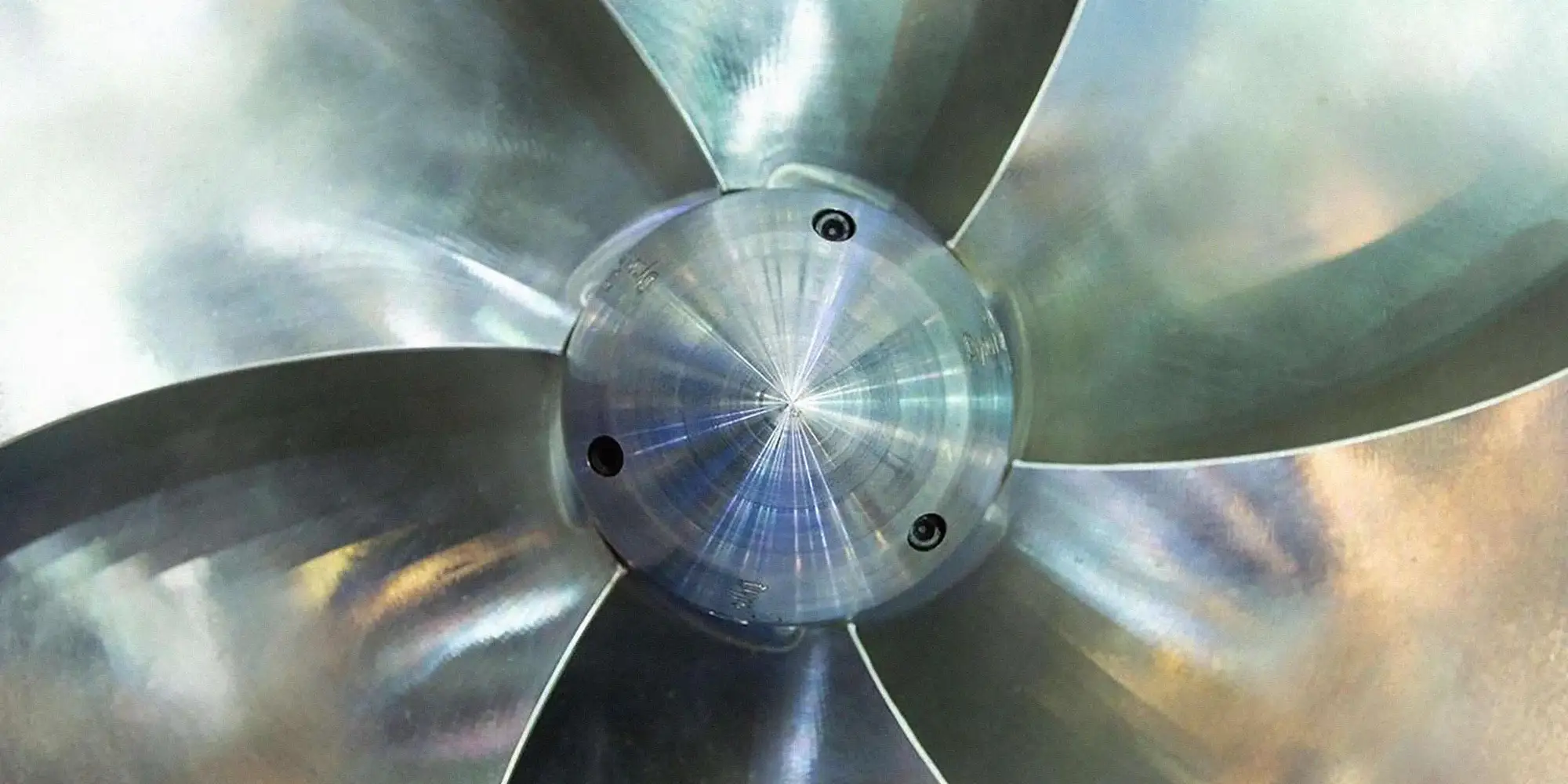

Development of an optimised propeller shaft design

Our customer required support for the design of a large marine propeller and shaft line for a new fleet of naval vessels. This project required...

In simple terms, Model-based systems engineering (MBSE), sometimes called Model-based design (MBD), is not only the use of models within the engineering design process but the elevation of models to the core of the design process, supporting and replacing traditional textual documents as the primary source of the design. Traditionally, a design for a system or equipment is developed from requirements with a specification capturing how the proposed design will meet those requirements. Instead, MBSE allows systematic development of the design from the requirements, with the design represented by different types of models, which can demonstrate that the requirements are met.

As an MBSE engineer, I work with other systems and mechanical design engineers to develop overall system models that satisfy the requirements. This is not a “one-size-fits-all” approach, there may well be many different models for different purposes, such as functional decomposition models, interface models and dynamic performance models. It is important to establish a good process where there is a single source of data that can then be leveraged by the many engineers that need it.

The models initially may be at a high level, such as aircraft level, then as the model and design develop this will transition down to system and equipment level. These same models can then be utilised later in the design life cycle to help verify the system design during testing and to support certification activities.

Aircraft are highly complex with many conflicting requirements. With the continued strive for better performance, cost-effectiveness, safety, reliability, maintainability, it is no longer possible to design these multi-system interfacing platforms without undergoing detailed analyses. Furthermore, the sooner these analyses take place, the quicker potential problems can be found, leading to more straightforward and therefore cheaper solutions. For example, if some problem is found during physical test, then the fix for this could delay the program and be very expensive to retrospectively solve the issues. Through MBSE, analysis is continually being performed, assessing the design, running concept trade-offs and optimisations. Any problems identified are significantly quicker and cheaper to solve at this stage.

For example, if some problem is found during physical test, then the fix for this could delay the program and be very expensive to retrospectively solve the issues. Through MBSE, analysis is continually being performed, assessing the design, running concept trade-offs and optimisations. Any problems identified are significantly quicker and cheaper to solve at this stage.

Aircraft are built of thousands of components from many different suppliers. This means that information and data must be passed (typically as textual specifications) between these stakeholders. This can cause problems in terms of interpretation, updating data, and again data relating from one system affecting another. If there exists a “single source of truth” which is encapsulated within a modelling environment, provided good processes are followed, this can reduce the possibility of misinterpretation and ensure the correct data is relayed.

We are hearing so much about MBSE right now within the aerospace sector as aircraft systems are becoming more complex, due to the increasing functions, which bring improved performance and increased safety. MBSE can help to keep development times down, even with this increased complexity. Additionally, with this increasing complexity, unwanted and unexpected interactions between systems can appear. Modelling techniques offer real advantages over traditional methods when evaluating potential system interactions. For example, knowing the hydraulic flow demanded by the landing gear system during gear retraction following take-off, will help size the hydraulic system and design the control logic to ensure there is enough hydraulic power available for the flight control systems.

We are hearing so much about MBSE right now within the aerospace sector as aircraft systems are becoming more complex, due to the increasing functions, which bring improved performance and increased safety.

It should also be noted that with changing emphasis within the industry, such as with electrification and urban air mobility, newer technologies and problems are being introduced. Modelling techniques can really help understand and solve these problems at an early stage and de-risk the products.

Modelling, analysis and MBSE is core to what Stirling Dynamics do within the aerospace and marine sectors. Within aerospace, Stirling Dynamics recently worked on a regional jet project where we developed models for all aircraft systems. This meant that each system could be analysed individually to verify that the design meets the performance and safety requirements. However, the real power of this approach was to integrate the system models together. When doing this, the interactions between the systems can be assessed, in unusual scenarios such as failure cases. This showed that how one failure in one system could have a detrimental effect on another system. Once these unwanted interactions were found, the models were used to study different design concepts to rectify the issues.

MBSE can also be applied at the equipment level. For example, Stirling Dynamics recently undertook the design of an electro-hydrostatic flight control actuator. The actuator consists of an electric motor, hydraulic pump, various hydraulic valves, and a hydraulic ram. Preliminary models were constructed for the actuator to first validate the top-level requirements. During this process, the model was used to generate requirements for the individual components of the actuator. As the mechanical design of components was developed using CAD tools, the performance models evolved to include more detail, which then allowed for detailed analysis and further design refinement. The final output was a design that could be demonstrated to satisfy all the requirements and pass the critical design reviews and we were ultimately able to complete the design much faster using these model-based approaches.

To learn more about MBSE, click here to download our free MBSE whitepaper.

Our customer required support for the design of a large marine propeller and shaft line for a new fleet of naval vessels. This project required...

2 min read

In the ever-evolving aerospace industry, innovation is the key to staying ahead. At Stirling Dynamics, we have been at the forefront of this...

As 2024 fades into the past, we at Stirling Dynamics take pride in reflecting on a year filled with remarkable achievements and milestones. Our...