Regional Aircraft Design Support

To achieve delivery of the company’s first regional jet aircraft programme, Mitsubishi Aerospace Corporation (MitAC) turned to Stirling for our...

With the rise of ageing airline fleets and a drive towards modernisation of passenger airliners, the inevitable time will come when operators face a difficult decision about what to do with assets that are not as commercially attractive as they once were.

How can companies repurpose their aircrafts? And how can this be done in an innovative and sustainable way, whilst being cost effective? In this blog post we discuss the benefits of aircraft conversion, Stirling Dynamics’ Passenger to Freighter (P2F) capability and the scope of P2F projects.

The lifecycle of a commercial aircraft can typically be extended by minor or major modifications to accommodate for a new role change. Converting a passenger aircraft to a freighter is an example of one of these changes. Passenger to Freighter (P2F) conversions are an attractive secondary prospect for older aircraft, as the airfreight market consistently relies on a mix of newly built freighters and passenger aircraft conversions.

According to Boeing’s World Air Cargo Forecast 2022 – 2041, over the next 20 years ‘the world’s cargo fleet will require nearly 2,800 production and converted freighters. A third of deliveries will consist of new production freighters, while the remaining two-thirds will be freighter conversions.

If you are in possession of a passenger aircraft that is no longer commercially viable in its current arrangement, the proposition of converting it to a freighter aircraft, as opposed to scrapping it, is an attractive and economical prospect. However, it is also a surprisingly complex engineering challenge.

The conversion of a passenger aircraft into a freighter is a complicated process requiring specialist technical skill sets. This is considered a “major change” and any changes to the original aircraft require detailed analysis of the proposed modifications, along with presentation of design compliance evidence, to the certification authorities for airworthiness clearance.

Changes to the airframe structure and increased payloads all need to be considered, as well as the installation of new systems suitable for the aircraft’s new function, all of which must comply with the rigorous certification process involved.

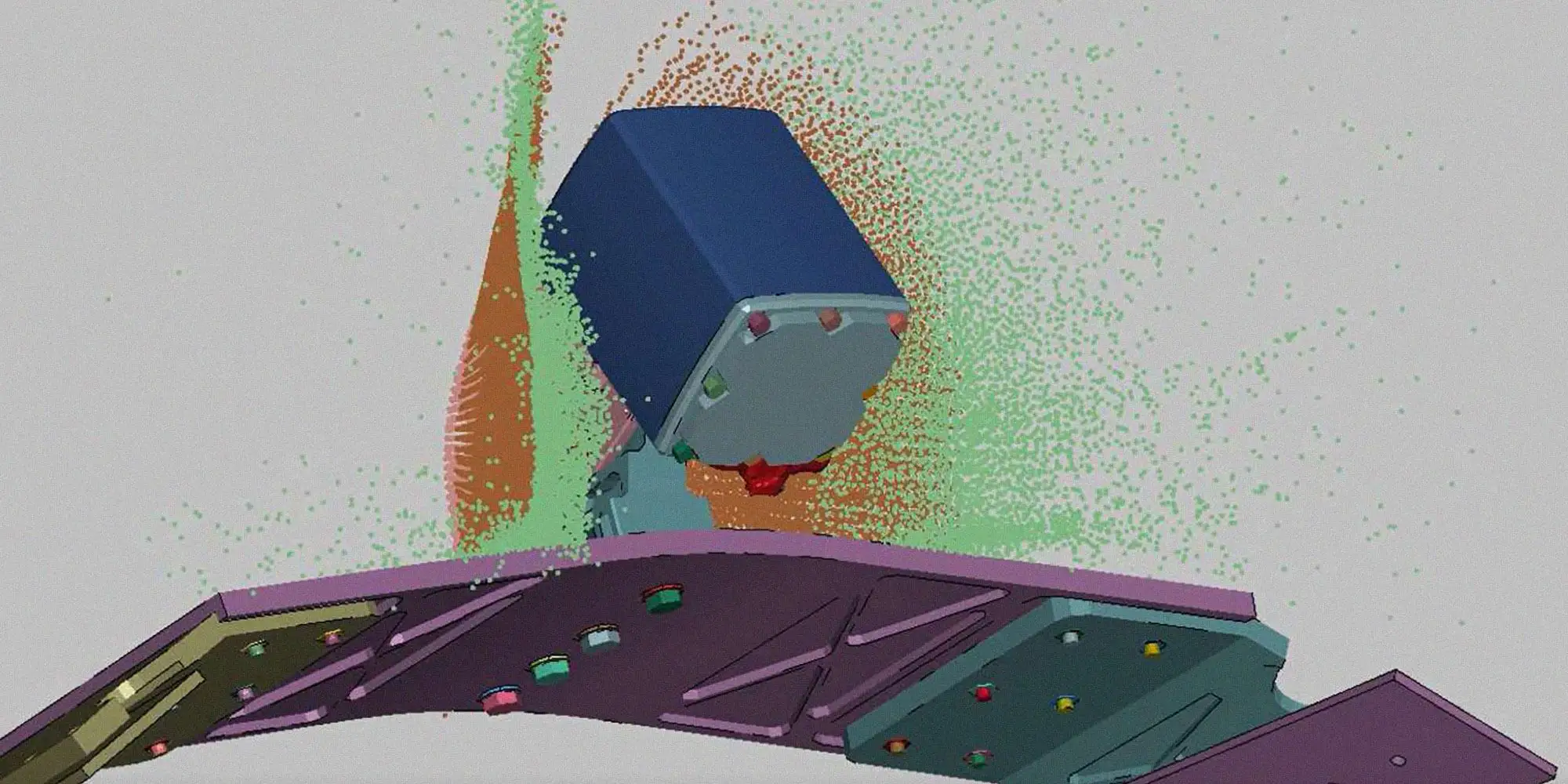

From our perspective at Stirling Dynamics, the technical complexity behind the scenes of a P2F conversion, can be a formidable undertaking, requiring the consideration of multiple aspects of the aircraft design and certification. A common misconception is that the conversion process is a physical process – simply stripping out the aircraft interior, installing a cargo door and plugging the windows – however, these physical changes are only possible after a great deal of critical analysis, to ensure the flight safety of the modified airframe.

The kind of work we get involved with includes, but is not limited to, the calculation of critical airframe loads, from which the design will evolve. Other aspects Stirling Dynamics is often asked to analyse are flutter analysis, systems integration and landing gear modifications.

Our EASA 21J design organisation can take the overall lead for such an STC project and manage all certification and compliance demonstration activities in close cooperation with the competent certification authorities for the concerned aircraft.

When we talk about ‘loads’ we are talking about the forces applied to the aircraft structure in both its normal and extreme operating conditions. This work is necessary, as the aircraft will be taking on different payload distributions as a freighter, and the resulting loads need to be analysed in-flight and, on the ground, to provide evidence that the aircraft can operate safely in its new role.

Often, we have limited aircraft data available, so we must supplement this with in-situ measurements and reverse engineering methods, to obtain the information we need to create representative simulation models.

These models are matched and validated against physical flight test measurements. Certification loads are derived from flight and ground simulations to meet the relevant requirements. The data collected is then passed onto the design team, who use it when designing the modifications to the aircraft. The ‘loads’ work is an important stage, in progressing the modification design.

In some specific cases, we can show compliance with certification requirements by demonstrating that the freighter modification does not produce ‘loads’ that are more critical than the passenger version. We have developed in-house ground simulation tools over the years, that are unique to Stirling Dynamics to help us achieve this and are one of the few independent companies in the world that can offer this experience and capability set.

P2F conversions will account for at least 60% of the freighter market, with the potential for more over the next 20 years within the industry. Conversion to freighter offers an ageing fleet a new lease on life and are an effective solution for the industry, which is something we very much endorse at Stirling Dynamics.

To achieve delivery of the company’s first regional jet aircraft programme, Mitsubishi Aerospace Corporation (MitAC) turned to Stirling for our...

Our customer, Helitune, is a market leader in the design and manufacture of Rotor Track & Balance equipment. The equipment and its supporting...

Our customer is currently modifying an Airbus A321-200 passenger aircraft into a freighter and required support for various aspects of the...