Landing Gear Design for Amphibious Aircraft

Building on our success as recognised landing gear design consultants, we were approached by a Chinese client that was developing an amphibious...

Airbus UK approached Stirling in 2001 to provide external expertise in a range of specialist areas to support their new aircraft design and development projects. As the working relationship grew, the scope of our support increased and after a short period covered all areas of flight physics, landing gear systems, fuel systems and materials and processes across all Airbus aircraft programmes (i.e. the A320 family, A380, A350, Widebody and A400M).

We have employed several different business models to facilitate this work, from onsite support through to fixed price packages that are responsible for delivering complete solutions.

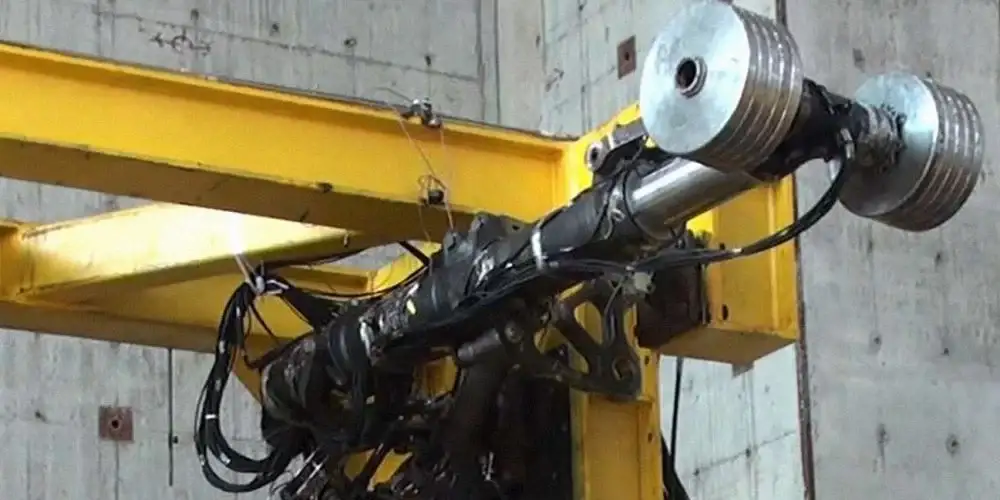

Activities conducted include: landing gear system design and Continued Product Development (CPD) (including braking, steering, retraction and extension systems); fuel system modelling; support to the future project office for conceptual studies; development of software tools to support loads calculations, aerodynamic database generation, landing gear design and mass estimations; and management of the UK Materials and Processes Laboratory, which conducts coupon testing and failure analysis and reporting.

A preferred supplier to Airbus UK for over 15 years, Stirling supports the company’s legacy fleet as well as new aircraft developments, with significant involvement in both aircraft programmes and internal Airbus R&T activities.

Building on our success as recognised landing gear design consultants, we were approached by a Chinese client that was developing an amphibious...

To achieve delivery of the company’s first regional jet aircraft programme, Mitsubishi Aerospace Corporation (MitAC) turned to Stirling for our...

During the development of their first aircraft with wing-mounted engines, Bombardier Aerospace approached us to provide an independent evaluation of...