Marine Propulsion

Complex analysis to deliver enhanced performance

Using our analysis capabilities to focus on specific elements of the propulsion solution and enhance outcomes. From propeller hull interaction to shaft line whirl resonance, we aim to deliver the optimum design solution.

Supporting marine propeller and shaft line development

Utilising industry leading toolsets

Stirling Dynamics is skilled in supporting marine propeller and shaft line development. Providing a range of services throughout the propeller development process we can produce preliminary propeller designs, loads and sensitivity studies for bespoke designs in addition to standard propeller series.

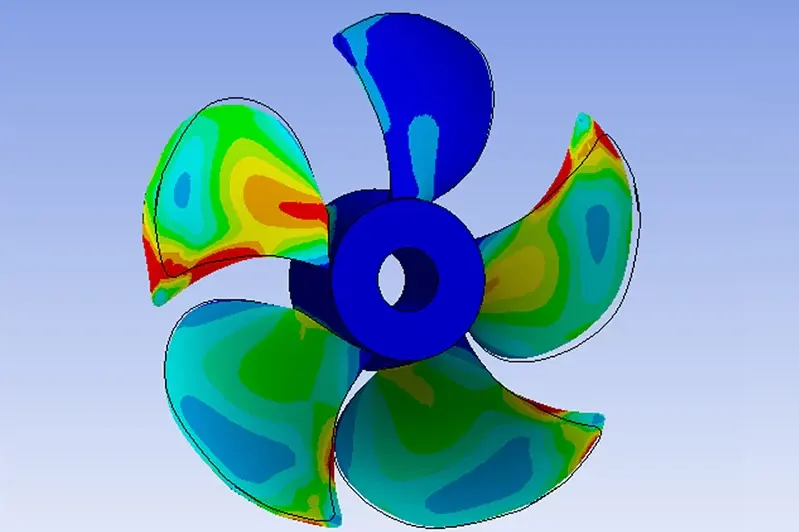

By utilising the latest industry-leading toolsets, Stirling Dynamics is able to provide high fidelity modelling of propeller, shaft line and hull flows for design validation of installed propellers and the prediction of operational loads. Our structures team can carry out high fidelity finite element analysis for strength and produce detailed CAD solid models for manufacture.

Propeller Shaft Design

DYNAMIC ANALYSIS OF PROPELLER SHAFT LINES

With a strong background in dynamic systems, we have undertaken dynamic analysis of propeller shaft lines, including whirl frequency analysis and shock analysis.

Our prediction of shaft whirl involved the creation of an Ansys 3D FE model of the propeller, shaft components, journal bearing contact mechanics and the stern structural stiffness to identify resonant frequencies for various shaft speeds and provide static analysis under gravitational loading. We have performed non-linear transient dynamic analysis of safety-critical shaft line components under shock loading in line with industry standards. Our experience extends to the specification of shaft balancing requirements to ensure low noise and vibration.

Supporting new propeller designs

NEW MARINE PROPELLER DESIGNS FOR OPTIMAL PERFORMANCE AND LOW NOISE

Stirling Dynamics is equipped to support development of new marine propeller designs for optimal performance and low noise, ensuring adequate strength and fatigue life. Our experience in rotary fluid dynamics enabled us to utilise industry-leading propeller design software and 3D computational fluid dynamics. Our skilled team of structural design engineers are able to provide detailed design of critical propeller features using SolidWorks 3D CAD software.

We can also conduct static and fatigue analysis of propeller design using 3D FEA for various operational and limit conditions using Ansys.